|

|

||

|

� 2001 to 2004 Astley Green Colliery Museum

|

| |

The ceilings and the wood block flooring is evidence that the Lodge originally housed the offices of the pit managers. The Lodge now used for housing a number of the smaller exhibits. These include a recreated colliery lamp room, a replica underground roadway display and a small winch engine from Agecroft Colliery.

|

Astley Green Colliery Museum Narrow houses the largest collection of colliery locomotives in the United Kingdom. Many of the locomotives have be donated or loaned to the museum. The existing 400 metres of line, running through the site, is currently used for freight demonstrations.

|

Amongst the exhibits housed in the Engine House is the largest steam winding engine ever used in the Lancashire Coalfield. Built by Messers' Yates & Thom in 1912, the twin tandem compound engine delivers 3,300 hp.

|

The capstan engine is housed between the legs of the headgear. Built by John Wood & Sons in the 1950s, for the Agecroft Colliery in Salford, it was used for re-roping the Koepe tower winder and for shaft inspection. The drum, of the capstan engine, alone weighs 65 tons.

|

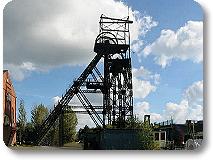

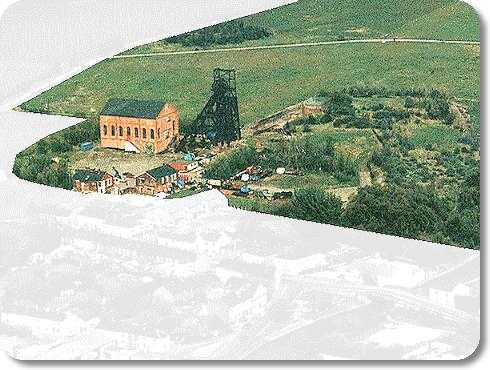

The steel lattice headgear for Number 1 Shaft is the only colliery headgear remaining in Lancashire. The structure, which is over 100 feet 30 metres high, was built by Head Wrightson & Co. in 1912 and replaced the original wooden shaft sinking headgear.

|

Built by Walker Brother of Wigan in 1940, the emergency winder was based at the Boothstown Mines Rescue Station throughout all of its working life. The emergency winder, which is trailer housing a winding drum and an 8 cylinder Gardner diesel engine, would be towed to collieries in the area when their main winding engine was out of commission.

|

The Steam Line includes a vertical boiler, a vertical weir pump used to feed water to the header tanks above the boiler or directly to the boiler, if required, and single cylinder horizontal engine made by Marshall's, which drives the circular saw used to cut the wood for the boiler. A number of other restored steam engines are included in the line up.

|

The Pit Bank was originally under a large building housing the tub track circuit where, tubs that had been brought up the shaft, headed off towards the screens. After discharging the coal, the tubs returned to the shaft. Some of the original track is still visible as are a number of tubs and a cage, from Bold Colliery.

|

A number of exhibits, once used in the coal mining industry, are included the Static Display.

|

The Garage building was originally the colliery's rescue room, with garage facilities below. Today the building houses the museum's offices and workshops.

|

The Bridgewater Canal was an important part of the colliery providing a means of transporting coal to a number of destinations including Barton Power Station using barges. The barges were loaded at the wharf side using steam cranes.

|